Introduction to LTL Transportation

Published: September 21, 2023

Last Updated: January 28, 2026

Less-than-Truckload (LTL) transportation is an integral part of the modern supply chain, offering businesses a flexible and cost-effective solution for transporting goods in volumes that do not require a full truckload.

This article will provide a comprehensive understanding of LTL transportation, including its benefits, how it works, and recommended best practices.

What is LTL Transportation?

LTL Transportation involves collecting small shipments from multiple shippers and combining them onto one truck. Each shipper is charged only for the space their freight takes up in the trailer.

Benefits of LTL Transportation

1. Cost Savings: LTL transportation enables businesses to pay only for the space they use in a trailer, making it a cost-effective solution compared to full truckload shipping and an excellent solution for small and e-commerce businesses.

2. More efficient supply chains and increased customer satisfaction: Without LTL transportation, shippers would need to either wait until they had enough freight to fill a truck or incorporate the cost of a full truckload into the price of smaller orders. LTL transportation allows shippers to deliver small orders quickly and cost-effectively, increasing customer satisfaction.

3. Environmentally Sustainable: As shippers can avoid moving small shipments via truckload service, LTL transportation consolidates many small shipments onto one truck, thus leading to fewer emissions and a smaller carbon footprint.

Subscribe!

Subscribe to receive the latest articles, newsletters, whitepapers, and industry news directly to your inbox.

"*" indicates required fields

What does a typical LTL shipment look like?

LTL shipments usually fit within the following parameters:

How are LTL Shipments Loaded in a Trailer?

A 53’ trailer is segmented into twenty-six 48” x 48” pallet positions or skid spots. This means that a 53’ trailer can accommodate up to 26 pallets with a 48” x 48” footprint.

When a pallet is too tall for more freight to be loaded above it, some carriers will consider that pallet to be taking up two pallet positions. For this reason, many LTL carriers will charge a premium for tall pallets that exceed a certain height. Typically, LTL carriers allow pallets to reach up to 72” in height before a surcharge is applied. Skids must not exceed 84” in height, as this is the maximum height a pallet can be before it is too tall to fit on a straight truck, which is typically used for local pickups and deliveries.

How Does LTL Transportation Work?

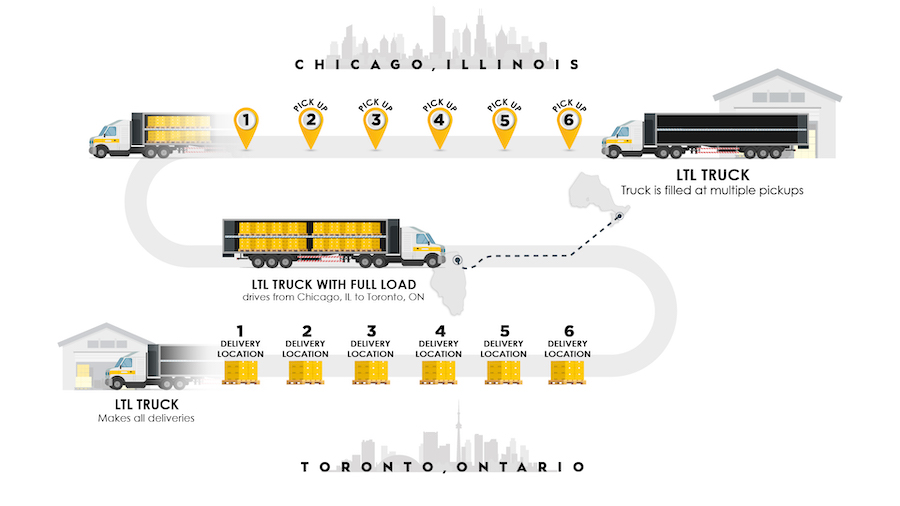

Direct LTL Service

Direct LTL service is a less common way to ship LTL freight and is more commonly done in Canada. Direct LTL service involves a truckload carrier picking up multiple small shipments within a close geographic area until their truck is full, driving to the destination, and delivering each shipment to receivers within a close geographic area in the order they were loaded. Using this method of LTL transportation, the first pallets on the truck are always the last to be delivered (First-On-Last-Off).

Direct LTL service is better suited to larger LTL shipments as the bulk of the cost is in the pickup. With larger loads, that cost is amortized over more freight, thus making the overall shipment less expensive to move. In contrast, smaller shipments can be more costly via direct LTL.

Since Direct LTL service is provided using one truck and one driver, you can expect better communication, visibility, and transit times. Further, because the freight is delivered in the order it is loaded, there is no cross-docking, reducing the risk of damages and losses. With all its benefits, direct LTL has a significant disadvantage – capacity. Direct LTL carriers are less common; thus, they have limited capacity and are not as widely available across geographic areas as LTL common carriers using the hub-and-spoke model.

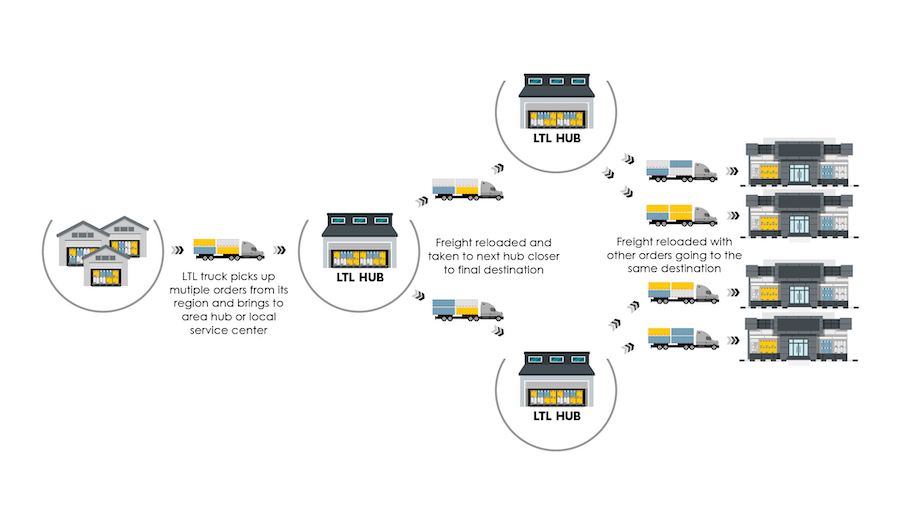

Hub and Spoke Network

Hub and Spoke systems involve local carriers gathering shipments from multiple shippers in a close geographic area and are the most common way to ship LTL. The carrier delivers the freight to an LTL distribution hub (or terminal) when their trailer is full. LTL carriers typically use straight trucks to do these pickups and deliveries.

LTL shipments are sorted and grouped at the distribution hub based on the distribution hub they are destined for next. When enough freight has been collected to fill a truck, it is loaded onto a highway truck and line-hauled to the next hub.

When the freight arrives at its distribution hub, it is again sorted and grouped based on where it is going next. Some freight may be headed to another distribution hub, while other loads may be directed to its final delivery.

Freight headed to its final delivery is sorted and grouped by destinations within a close geographic area. A local carrier will pick up the freight and deliver it to each final receiver.

Shipping LTL freight via a common carrier using the hub-and-spoke network has advantages and disadvantages:

- For smaller shipments, the hub-and-spoke model tends to be less expensive; conversely, larger shipments can become very expensive.

- It can sometimes take several days for a direct LTL carrier to pick up, so if dock space is an issue, this can cause frustration. Depending on the time of day a shipment is dispatched, the hub-and-spoke model can offer same-day or next-day pickup.

- Transit times are generally more extended in the hub-and-spoke model. One day is usually added for pickup, sorting at each distribution center, and delivery.

- As freight must be cross-docked 2+ times between pickup and delivery, there is an increased risk for losses and damages in the hub-and-spoke model.

- With direct LTL service, there is one truck and one driver; thus, communication and shipment visibility are optimal. Within the hub-and-spoke network, the actual location of a shipment can be lost if it misses a scan while moving between equipment and distribution hubs.

- LTL common carriers can pick up and deliver nearly anywhere in North America and have readily available capacity in contrast to direct LTL carriers.

Pricing LTL Shipments

LTL Shipments are priced using one of three models:

- Pallet – based on the number of pallet positions consumed in a trailer.

- Weight – based on the total weight of the shipment.

- Density & Cube – considers several factors, including density, stowability, liability, ease of handling, and cubic weight. In this model, freight is classified using the NMFC classification system.

While the pallet and weight pricing models are easy to understand, the density & cube model is more complex. We recommend checking out our upcoming article on Pricing LTL Shipments to learn more.

In addition to LTL rates, shippers should be aware of potential accessorial charges. You can learn more about LTL accessorials and best practices for cost avoidance in our upcoming article on LTL Accessorials.

LTL Best Practices

When shipping LTL freight, there are several things you can do to ensure accurate pricing, optimal transit time, and overall satisfaction:

- Accurate Measuring and Weighing: Most LTL shipments are based on either the Weight or Density & Cube pricing models. For this reason, accurately measuring and weighing each pallet is critical to accurate pricing.

- Make sure to calibrate your weigh scales regularly to accurately report each pallet’s weight.

- Best practices suggest never guessing or estimating a pallet’s length, width, height, or weight. If an LTL carrier suspects a shipment’s dimensions and/or weight have not been reported correctly, they will inspect the freight and adjust the rate to reflect this. This can lead to unanticipated freight charges.

- Keep pickup and delivery windows flexible: The timing of LTL pickups and deliveries is dependent on uncontrollable circumstances, including weather, traffic between stops, and the speed at which each shipper/receiver loads/offloads their freight. Despite their best efforts, delays at or between stops can quickly throw a local driver off schedule, causing them to miss their subsequent pickup/delivery windows/appointments. Being flexible with pickup/delivery windows will reduce frustration and increase your customer experience.

- Load and offload efficiently: As mentioned above, delays caused by slow loading/offloading can significantly negatively impact a driver’s pickup/delivery schedule. For this reason, LTL carriers typically offer 30 minutes to load or offload freight from the trucks to ensure they keep as close to schedule as possible. Efficient loading/offloading will help you avoid detention fees.

- Communicate with your receiver: Understanding what services a receiver needs in advance is critical to avoiding unforeseen fees. Ask investigative questions about the receiver’s location, such as:

- Do you have a receiving dock?

- What are your hours?

- Do you require an appointment for delivery?

- Etc.

For example, suppose upon delivery, the consignee informs the delivery driver that a liftgate and inside delivery services are required to receive their freight. In that case, the driver will oblige, and fees will be applied regardless of if they were ordered. Knowing these details upfront will help you avoid surprise charges.

- Accurately complete paperwork: Accurate paperwork is essential to a smooth LTL shipment. This is especially true when shipping cross-border.

If, for example, one shipment on an LTL carrier’s truck does not have proper customs paperwork or causes border patrol to conduct an inspection, it will delay every shipment on the trailer. The load that causes those delays will be responsible for paying all fees and fines associated with the delay.

- Finally, manage expectations: Managing expectations effectively ensures you are happy with your LTL service. Inexperienced LTL shippers often become frustrated with their service provider when there are delays. While none of the following are meant to be excuses for poor service, it is essential to keep in mind:

- Remember that there is no profit or benefit in delaying your freight. Your LTL partner wants to move your shipment as efficiently as possible.

- If just one shipper or receiver delays their pickup or delivery, it will delay all subsequent pickups or deliveries. In the worst cases, this can push pickup/delivery to the next day as freight is delivered according to the First-On-Last-Off principle. While this is frustrating, it is out of the carrier’s control.

- If you have an urgent LTL shipment with a critical delivery date, shipping via LTL (especially via a common carrier) may not be the best choice. LTL transit times are not guaranteed and are subject to the delays and unforeseen circumstances mentioned above.

Suppose you have mission-critical freight that must be delivered on time to avoid costly consequences. In that case, we recommend exploring expedited transportation services that will move your fright through traditional channels quicker based on its urgency.

Choosing an LTL Partner

There are several key things to consider when choosing an LTL transportation partner:

- Coverage and Capacity: Look for an LTL partner that has a significant number of assets positioned in the geographic areas you need them to ensure you have sufficient capacity when and where you need it. Partnering with a 3PL, like TRAFFIX, can be your single-source solution to full North American coverage and extensive capacity and give you a choice regarding the carriers, transit times, pricing, and service levels you choose.

- Proven Track Record of Success: Has the LTL provider been in service for a number of years with a loyal customer base? This is a good indication of their customer service, reliability, and KPI performance.

- Pricing: Rates are an important consideration when choosing any transportation partner. Work with a provider eager to understand your business goals and budget and willing to negotiate rates on your behalf. While pricing is often a critical factor in choosing any vendor, we recommend that it is not your only consideration, as lower rates can mean lesser service.

- Financial Stability: A quick search on the LTL providers you are considering to learn about their current financial status is a good idea. Even carriers that have been in business for a long time can struggle with profitability and debt issues. For example, Consolidated Freightways went out of business in 2022, and (to the surprise of many) YRC closed its doors in 2023.

Other Considerations: Additional things to consider when looking for an LTL partner include:

- What is your volume? Does the provider offer solutions to accommodate your shipping levels?

- Can they adapt quickly to changes in demand?

- Do they offer a team of expert consultants who can help you optimize your LTL supply chain?

- Do they offer technology solutions, such as TRAFFIX’ cloud-based TMS, to help you manage your LTL operation?

- Do they offer back-office support services such as accessorial management, invoice auditing, etc.?

- Can they help you scale your business from a transactional LTL shipper to a contractual to a fully-managed LTL operation? To learn more about the different levels of LTL service, check out our upcoming article on Outsourced LTL Solutions.

Conclusion

Less-than-Truckload (LTL) transportation is vital in today’s supply chain landscape. Its cost-saving benefits, efficiency in handling small shipments, and positive environmental impact make it a compelling choice for businesses. Whether through direct LTL service or the hub-and-spoke network, understanding the nuances of LTL shipping is crucial. Accurate pricing, flexible scheduling, efficient loading, and proactive communication with receivers are key best practices to ensure successful LTL shipments.

A strategic partnership with the right LTL provider can streamline logistics operations and contribute to your business’s success. As you delve deeper into the world of LTL transportation, stay tuned for our upcoming articles on pricing and accessorials, which will provide even more insights into optimizing your LTL strategy.

To learn more about LTL transportation, contact us today!