The Complete Guide to Temperature-Controlled Transportation

Published: January 29, 2026

Last Updated: February 10, 2026

Integrity. Stability. Control.

In temperature-controlled logistics, a small temperature change can alter the entire shipment. Everything from texture and chemistry to shelf life, safety, and compliance depends on keeping the right environment throughout transit. Once stability is lost, product integrity can begin to deteriorate long before delivery, and the consequences may only surface afterward.

Temperature-controlled transportation exists to prevent these failures. It is a system built on planning, equipment, proactive maintenance, communication, and visibility. More than simply “keeping freight cold”, it requires understanding how products behave, how temperature shifts occur, and how to design a cold chain that preserves stability from origin to delivery.

This guide aims to make temperature-controlled logistics easier to understand. Whether the freight involves food, pharmaceuticals, chemicals, cosmetics, or any temperature-sensitive consumer goods, the insights that follow help you navigate this mode with clarity and make confident decisions.

What Is Temperature-

Controlled Transportation?

Temperature-controlled transportation refers to the movement of goods that must remain within a specific temperature range to preserve quality, safety, or regulatory compliance. This includes frozen products, chilled items, ambient goods that require stability, and loads that must stay warm enough to avoid freezing.

At its core, temperature control is about maintaining equilibrium. Many shippers assume it only applies to cold or frozen freight, but the spectrum is much broader. For example, chocolate melts with minor heat exposure; cosmetics separate; chemicals degrade; and pharmaceuticals can lose efficacy with slight temperature fluctuations.

A reefer trailer cannot correct upstream issues. The cold chain begins long before a truck is dispatched – it begins with the preparation, packaging, handling, and temperature of the product when it is loaded.

Understanding these nuances is the foundation of effective temperature-controlled shipping.

Temperature Ranges

and Why They Matter

Temperature requirements vary significantly across industries and commodities. Setting the wrong range or misunderstanding product sensitivity is one of the leading causes of temperature-related claims.

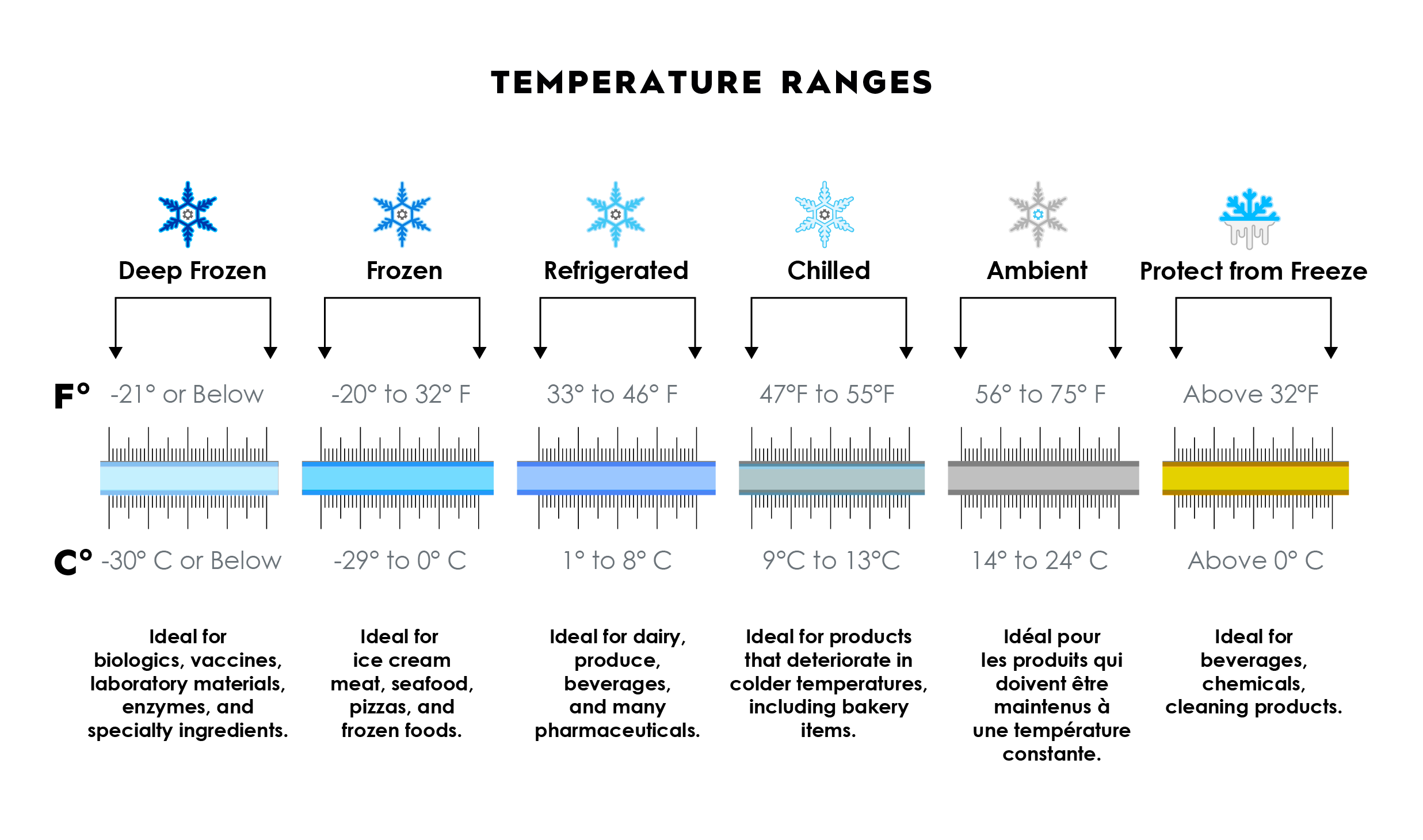

Below are the most common operational temperature ranges in North American logistics:

- Deep Frozen

Typically –40°F to –4°F (–40°C to –20°C). Used for biologics, vaccines, laboratory materials, enzymes, and specialty ingredients. Deep frozen shipments often require specialized equipment or dry ice systems to maintain such extremely low temperatures.

- Frozen

Generally –13°F to 14°F (–25°C to –10°C). Contrary to popular belief, “frozen” does not mean 32°F (0°C). Products such as meat, seafood, ice cream, and frozen foods must remain well below the freezing point, typically below 14°F (–10°C), to preserve structure, texture, and safety.

- Refrigerated / Cold Shipping

Typically 34°F to 46°F (1°C to 8°C). Common for dairy, produce, beverages, and many pharmaceuticals. For some products, even a small deviation can accelerate spoilage or degrade product performance.

- Chilled (Often referred to as “Keep Fresh”)

Generally 46°F to 55°F (8°C to 13°C). This range is used for products that deteriorate in colder temperatures, including bakery items and certain produce varieties that are sensitive to chilling injury.

- Controlled Ambient

Usually 55°F to 75°F (13°C to 24°C). Products commonly shipped within this temperature range include chocolate, cosmetics, chemicals, wine, and electronics that require protection from heat fluctuations.

- Heated / Protect-From-Freeze

At this temperature range, freight is kept above 32°F (0°C) in winter. This is essential for beverages, chemicals, cleaning products, and other freeze-sensitive consumer goods.

Understanding temperature thresholds is the first step to a successful shipment. Consistently maintaining optimal trailer conditions requires experience, the right processes, and well-maintained equipment.

Clarifying Terminology

In temperature-controlled logistics, several terms are often used interchangeably, even though they refer to very different things. This section clarifies how temperature control, reefer equipment, and heated service differ, and why understanding those distinctions matters.

- Temperature control is the overarching concept. It refers to maintaining a specific thermal environment throughout transit and includes heated, ambient, refrigerated, chilled, frozen, and deep-frozen ranges. It also encompasses decisions around airflow, operating mode, and equipment selection.

- A reefer trailer refers to refrigerated trailers designed to actively control temperature, primarily to preserve cold or frozen products during transport.

- Heated service is a form of temperature-controlled transportation used to prevent freight from freezing in cold weather.

Understanding these distinctions helps shippers communicate properly with their transportation provider when setting up shipments.

Reefers are made to maintain temperature, not fix a temperature mistake. If freight is not pre-cooled or frozen before loading, the reefer can’t save it. Pre-loading best practices are critical to product integrity. – Upton Stover

Operating Modes:

Cycle vs Continuous

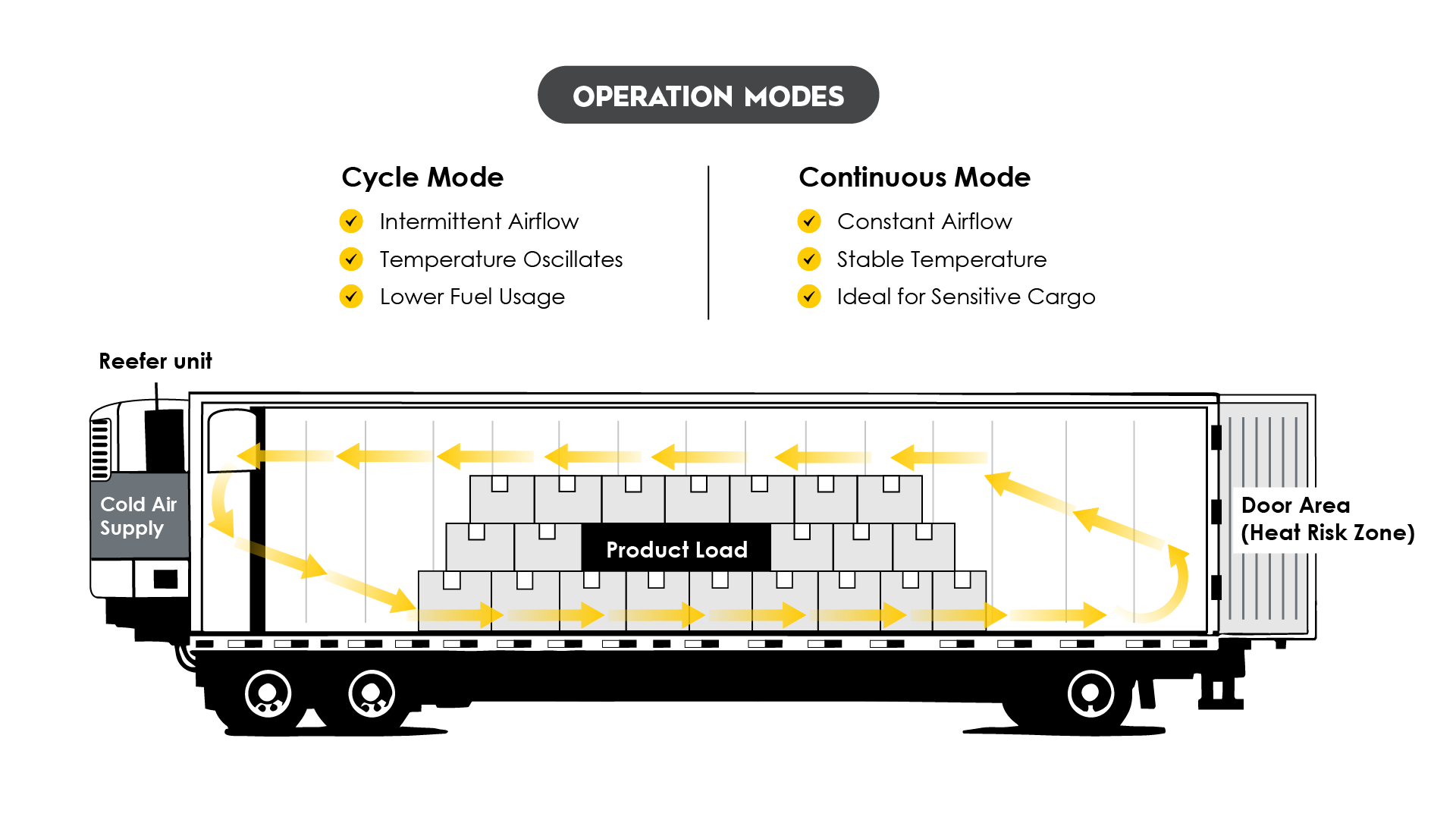

Beyond equipment and temperature range, operating mode is another important requirement in temperature-controlled transportation. This choice affects airflow consistency, temperature stability, and how freight responds to door openings and stops.

Cycle mode turns the refrigeration unit on and off to maintain the set temperature. It conserves fuel and is suitable for freight that is less sensitive to minor temperature fluctuations.

Cycle mode is often appropriate for:

- Controlled ambient shipments

- Certain packaged consumer goods

- Products with lower sensitivity to airflow interruptions

Continuous mode runs the unit consistently to maintain steady airflow and minimize temperature variation. It is typically required for freight that is highly sensitive to temperature changes or airflow disruption.

Continuous mode is commonly used for:

- Fresh produce

- Meat and poultry

- Pharmaceuticals

- Ice cream and frozen foods

Selecting the correct mode ensures the equipment supports the product’s behavior rather than working against it.

When to Use Temperature-

Controlled Transportation

Temperature-controlled transportation is required whenever product quality, safety, or regulatory compliance depends on maintaining a stable environment. Common use cases include:

- Perishables and food products, such as fresh produce, dairy, meat, seafood, beverages, and frozen foods, which rely on precise temperature control to inhibit bacterial growth and preserve freshness.

- Pharmaceuticals and medical goods, which often have narrow temperature tolerances where even brief deviations can reduce efficacy or render products unusable.

- Cosmetics, chocolate, and beauty products, which react quickly to heat, leading to melting, separation, or structural changes that affect quality and appearance.

- Chemicals and hazardous materials, where temperature fluctuations can cause instability, accelerate degradation, or create safety risks.

- Consumer goods, including electronics, adhesives, and specialty materials that require temperature stability even when labeling does not make it obvious.

A lot of ambient freight actually needs temp control. The product might not say ‘keep refrigerated’ but it cannot survive heat swings. Controlled ambient protects more freight than people realize. — Upton Stover

To reduce costs, some shippers assume their products can move in dry vans during winter or mild weather, only to discover that the shipment encountered unexpected temperature extremes during transit—resulting in compromised quality. Chocolate, nutrition bars, cosmetics, and other heat- or cold-sensitive goods are especially vulnerable, as even brief exposure outside a controlled range can lead to issues such as blooming, separation, or structural damage.

Temperature Controlled Equipment

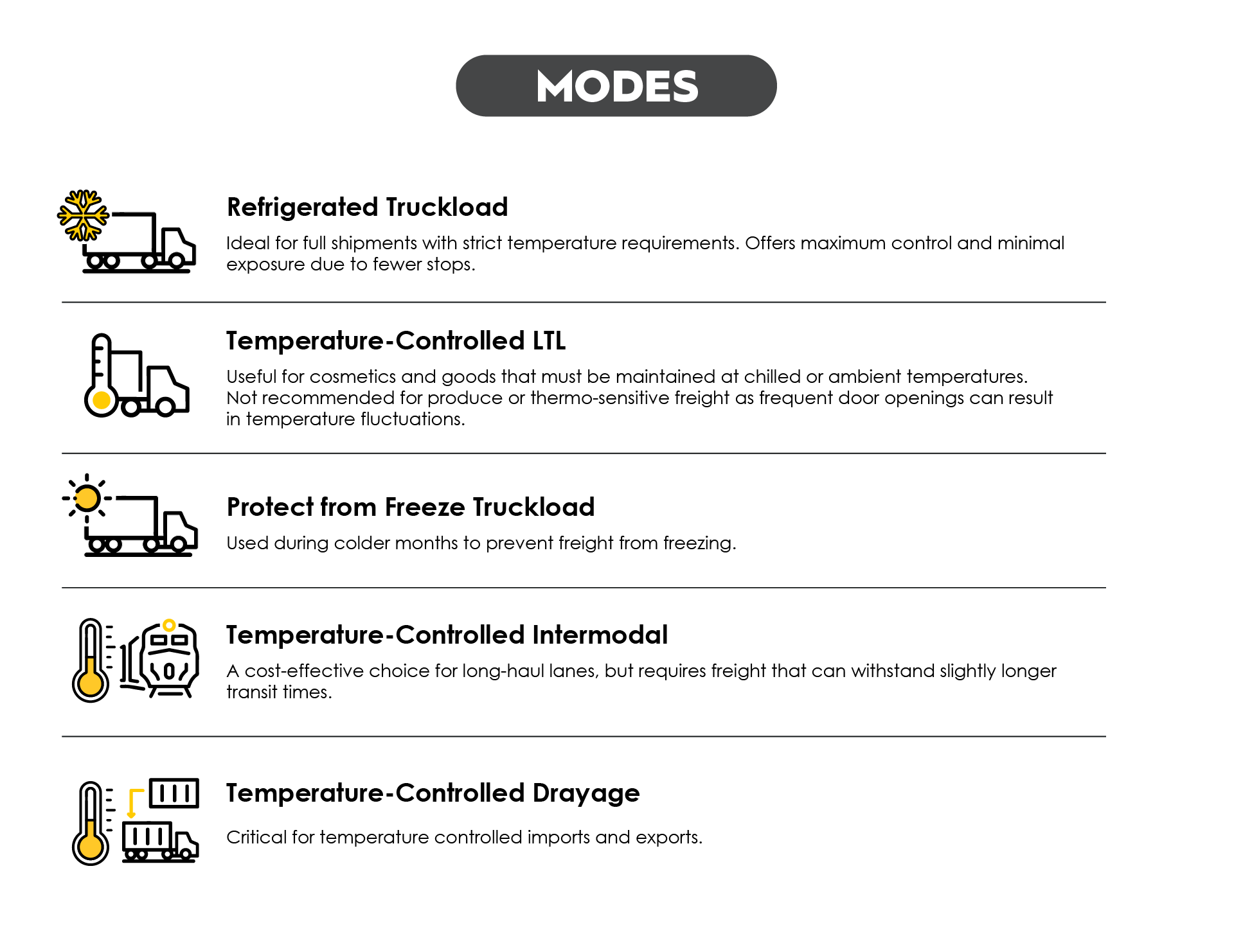

Temperature-controlled freight can move across multiple transportation modes, including truckload, LTL, intermodal, and drayage, each suited to different commodities, volumes, and lane requirements.

Refrigerated Truckload

Refrigerated truckload is best suited for shipments with strict temperature requirements and limited tolerance for exposure. Because the freight moves on a dedicated trailer with minimal stops, this mode offers the highest level of control over temperature stability, airflow, and transit time.

It is commonly used for fresh produce, meat, poultry, dairy, frozen foods, pharmaceuticals, and other highly temperature-sensitive products.

Refrigerated truckload is often the preferred option when:

- Temperature sensitivity is high

- Transit time must be tightly controlled

- Door openings, dwell time and handling must be kept to an absolute minimum

- And when shelf life or product efficacy depends on consistent conditions

Temperature-Controlled LTL

Temperature-controlled LTL can be effective for less temperature-sensitive commodities, but it requires careful planning and strict product compatibility. Because all freight on a trailer must be maintained within the same temperature range, freight must be consolidated with products that share not only temperature requirements but also regulatory compatibility. This restricts the ability to mix commodities such as food and chemicals, or to ship high-odor products alongside goods that are susceptible to odor absorption, significantly limiting capacity and routing options.

Because LTL involves multiple stops and frequent door openings, temperature exposure increases with each handoff. For this reason, temp-controlled LTL is generally less suitable for highly sensitive products such as fresh produce.

In some cases, walled trailers are used to divide a single trailer into multiple temperature zones, allowing compatible freight to move together. Some of these trailers rely on a single refrigeration unit and bulkheads, which can restrict airflow and create hot or cold spots between compartments. Newer equipment may use fans between bulkheads or separate evaporator units for each section, along with individual temperature controllers for each zone.

As an alternative, milk-run or multi-stop shipments are often used to balance efficiency with improved temperature stability. While this approach offers better control than LTL, it still involves dwell time at each delivery location and repeated door openings, which can expose freight to temperature fluctuations and increase the risk of temperature deviations.

Heated Trucks

Heated trucks are used in protect-from-freeze service which keeps freight above 32°F (0°C) during cold weather conditions. This service is critical for products that do not require cooling but are damaged by exposure to temperatures below freezing.

Common applications include:

- Beverages and liquid products

- Chemicals and cleaning solutions

- Personal care and household goods

Intermodal Temperature-Controlled

Transitioning temperature-controlled shipments from over-the-road to rail can offer benefits such as reduced costs, lower carbon emissions and increased/more consistent capacity.

Temperature-controlled rail shipments use refrigerated containers designed to maintain a set temperature throughout multi-day transit. These containers are powered with genset units – diesel-powered power generators attached to temperature-controlled containers or chassis.

Compared to truckload, intermodal reefer containers typically offer:

- Less airflow flexibility than a standard trailer

- Limited access to the freight once sealed

- Longer transit times due to rail schedules and terminal handoffs

For this reason, intermodal temperature control is best suited for freight that can tolerate slightly longer transit times and minimal intervention..

Successful execution depends on:

- Proper container pre-cooling

- Fuel management

- Continuous monitoring during rail movement

Intermodal can be a cost-effective option when lane stability and product tolerance align.

Drayage and Port Services

Temperature-controlled drayage refers to the short-haul movement of refrigerated, frozen, or heated containers between ports or rail yards and nearby shipping or receiving facilities. These moves typically use refrigerated containers mounted on chassis with gensets, rather than standard dry containers.

Although drayage distances are relatively short, maintaining temperature integrity requires additional attention due to several factors:

- Port congestion and terminal dwell times: Refrigerated containers are ideally delivered the same day or next day. Extended dwell increases the risk of equipment issues or power interruptions, particularly when containers sit for multiple days.

- Genset availability: Most ports rely on shared genset pools that operate on a first-come, first-served basis, creating uncertainty around power availability at pickup and during terminal waits.

Temperature performance during drayage depends heavily on:

- Container condition and completion of a proper pre-trip inspection

- Adequate fuel or power while waiting at terminals, including access to plug-ins where available

- Close coordination with vessel schedules, terminal appointment windows, and drayage providers

Because port delays are common, temperature-controlled drayage often represents one of the most vulnerable segments of the cold chain – despite covering the fewest miles. For this reason, it is imperative to partner with a drayage provider that has experience handling temperature controlled shipments.

Pre-Cooling

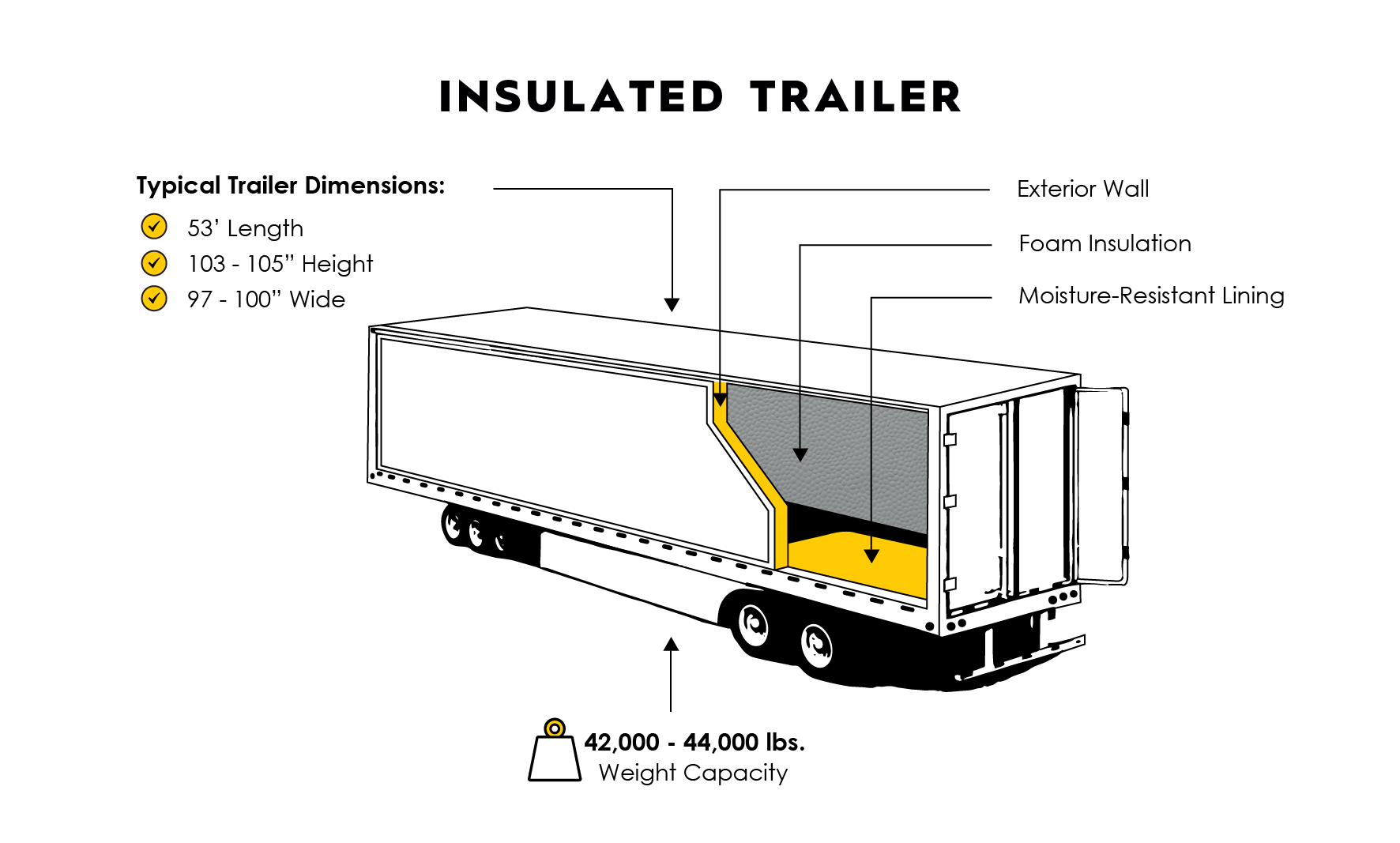

Pre-cooling applies to both the equipment and the product being shipped. The trailer must arrive at the shipper preconditioned to the required temperature, and the freight itself must already be within the specified range before loading.

A cold trailer cannot compensate for warm product. When freight is loaded above its target temperature, the refrigeration unit works to stabilize the air while the product continues to release heat. This imbalance often leads to early temperature deviations that cannot be corrected later in transit.

Pre-cooling is a shared responsibility between the shipper and the transportation provider and is a critical requirement at pickup.

Temperature Monitoring

The set point is the temperature programmed into the refrigeration unit and serves as the target the reefer works to maintain. While it defines how the unit operates, it does not always reflect the exact temperature surrounding the freight at every moment.

Box temperature represents the actual conditions inside the trailer. When equipment is operating correctly and freight is properly prepared, the box temperature is designed to closely track the set point. Temporary deviations may occur due to factors such as loading activity, door openings, airflow patterns, ambient weather, or dwell time, but the reefer actively works to restore the target range.

Monitoring both the set point and box temperature provides a more complete picture of temperature control and helps teams detect and address deviations early – particularly during loading, stops, and delays.

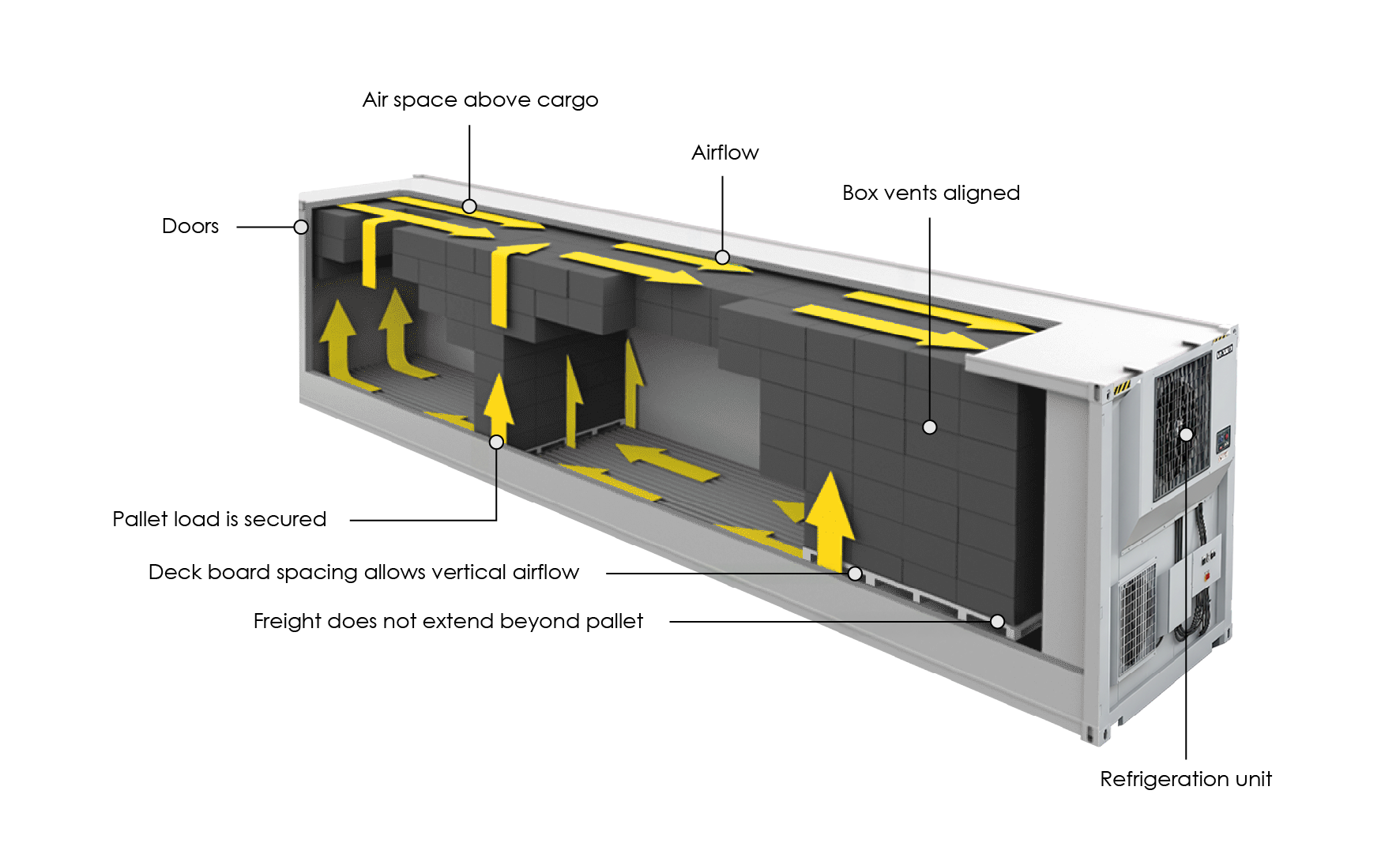

Airflow and

Load Configuration

Proper airflow is essential to maintaining consistent temperature throughout the trailer. Cold air must circulate freely around and through the freight to prevent hot or cold pockets.

Issues often arise when:

- Air chutes are blocked

- Pallets are stacked too tightly

- Freight is loaded flush against trailer walls

Even with the correct set point, restricted airflow can cause localized temperature drift and uneven cooling, which is especially critical for sensitive products.

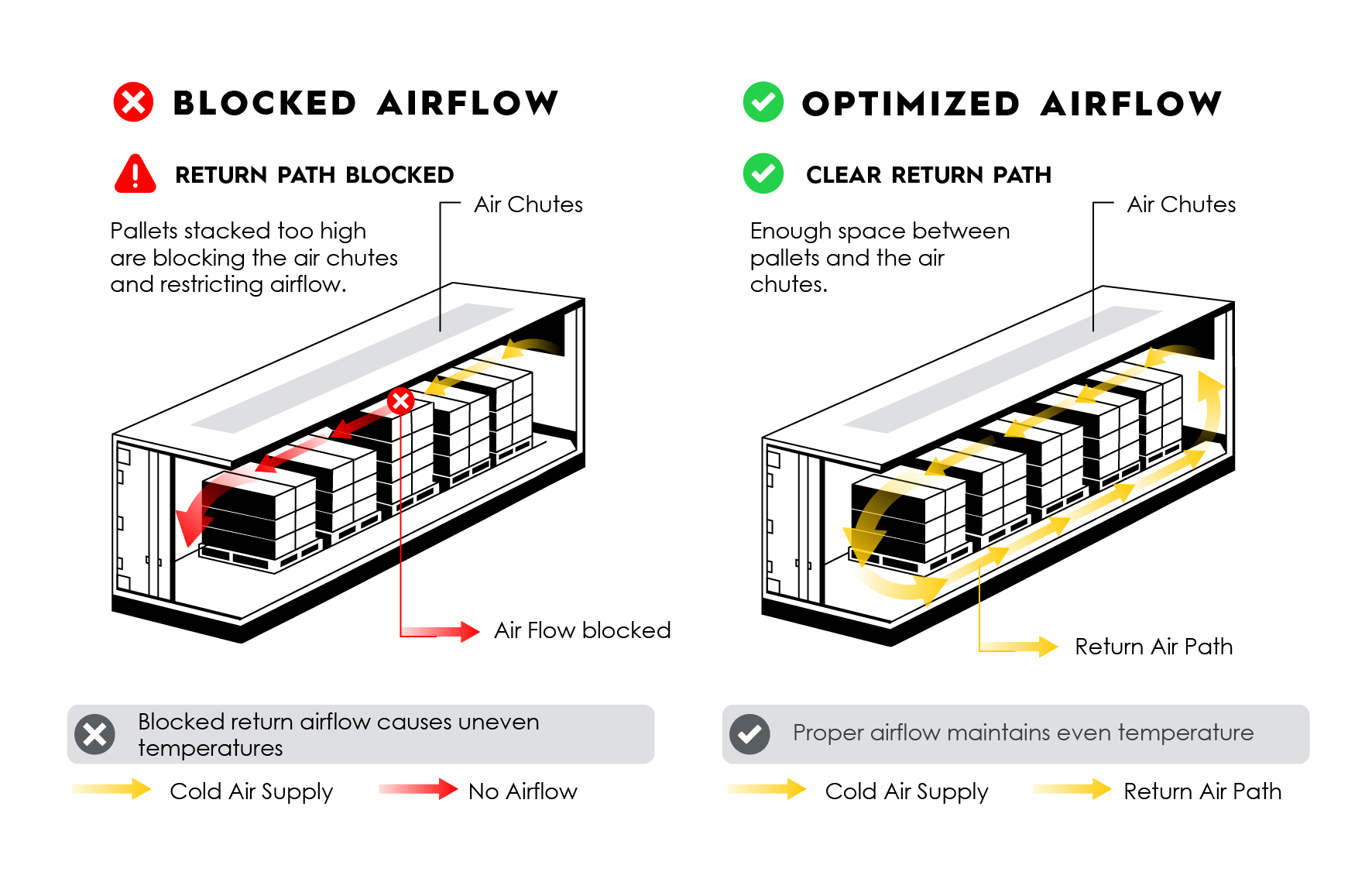

The diagram below illustrates how improper loading and blocked return air paths disrupt airflow, compared to an optimized configuration that allows air to circulate evenly throughout the trailer.

Washouts and Allergen Protocols

Trailers used for food-grade or allergen-sensitive freight must be properly washed, dried, and documented before loading. Inadequate washouts can introduce contamination risks through residue, debris, or lingering odors from prior loads.

Moisture left behind after washing can also create issues, including odor transfer or condensation that affects packaging integrity. Allowing sufficient dry time is just as important as the wash itself.

If a trailer is not properly cleaned or the washout documented, freight may be rejected at pickup or delivery.

Produce Season

Temperature-controlled capacity is highly seasonal. Weather patterns, harvest cycles, and consumer demand all influence equipment availability, transit conditions, and the level of temperature control required throughout the year. As conditions change, planning and execution must adjust accordingly.

During spring and summer harvests, demand for refrigerated truckload capacity increases significantly as fresh produce volumes move from growing regions to distribution centers across North America. This surge tightens capacity, increases competition for equipment, and often leads to longer lead times and higher rates.

Because of these pressures, produce season often requires:

- Earlier planning and carrier commitment

- Greater attention to pre-cooling and loading discipline

- Contingency planning for congestion and dwell

During produce season, shippers may consider incorporating temperature-controlled intermodal into their supply chains to increase capacity and stabilize pricing for commodities that are a good fit.

Produce season changes everything. What is easy in March can become a challenge in June. Planning ahead is the only way to maintain stability. — Upton Stover

Cross-Border Considerations

Temperature-controlled shipping across the U.S., Canadian, and Mexican borders introduces additional layers of complexity beyond domestic moves. Inspections, documentation, fuel management, and handoffs between carriers all influence temperature stability and must be planned as part of the cold chain.

Inspection Requirements

While meat, produce, and agricultural products are among the most commonly inspected commodities, they are not the only ones subject to border inspections. Pharmaceuticals, chemicals, food-grade consumer goods, and other regulated products may also be selected for review.

Inspections introduce dwell time that can vary widely based on border location, season, staffing levels, and shipment profile.

Temperature Verification

Border officials may request temperature readings, reefer settings, seal verification, or documentation confirming that temperature requirements have been maintained throughout transit. Proper documentation and monitoring help demonstrate compliance and reduce dwell time.

Fuel Management

Proper fuel management is critical for all temperature-controlled shipments, but it becomes especially important during cross-border moves where delays are more likely.

Peak seasons, staffing shortages, weather events, or congestion can extend dwell time at the border. During these periods, reefer units must operate independently for longer durations to maintain temperature stability.

Ensuring adequate fuel levels before arrival helps protect against:

- Extended inspection queues

- Overnight holds

- Unplanned delays during clearance

Fuel planning is not a contingency. It is a baseline requirement for preserving temperature control across borders.

Cold Cross-Docking

Between the U.S. and Canada, temperature-controlled freight often clears without entering storage, moving directly from shipper to receiver. Storage is less common but may be required in specific inspection or delay scenarios.

Between the U.S. and Mexico, cold cross-docking is far more common. In many cases, the drayage carrier that crosses the border does not deliver freight within the U.S. Instead, the load is transferred to a domestic carrier for onward movement. During this handoff, freight may be staged in temperature-controlled facilities to preserve integrity.

Understanding when and where cold cross-docking is likely to occur allows shippers to plan for additional handling, dwell, and monitoring without compromising product quality.

Leveraging CTPAT (Customs Trade Partnership Against Terrorism) Certified Carriers

Using C-TPAT–certified carriers can help temperature-controlled shipments cross the border more efficiently by reducing the likelihood of delays and inspections. These carriers follow validated security and compliance practices, which often result in expedited processing at the border. Fewer interruptions mean less dwell time, helping maintain temperature stability and protect product integrity during transit.

Some products cannot afford even small variations. Ice cream is a perfect example. If it softens once, refreezing doesn’t undo the damage. — Upton Stover

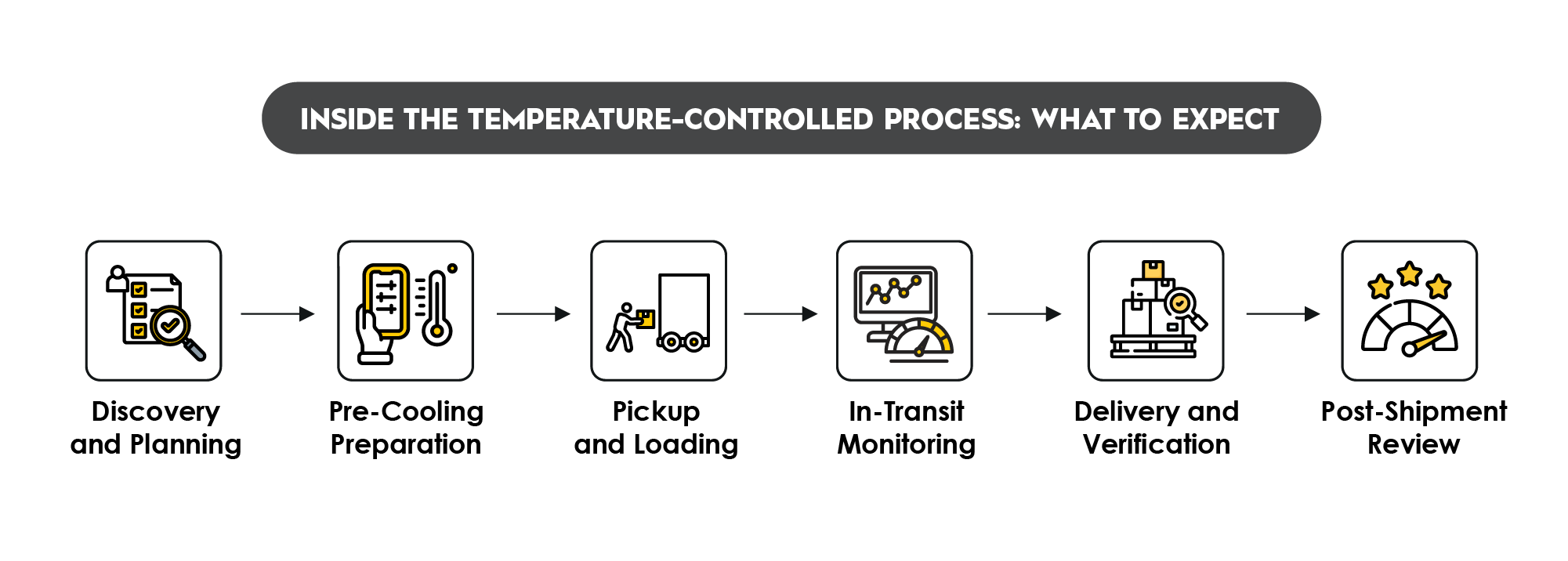

Scheduling Process

A reliable cold chain depends on proactive planning, disciplined execution, and continuous visibility. Below is an overview of what to expect when setting up a temperature-controlled shipment.

Step 1: Discovery and Planning

- Confirm the required temperature range in writing with your transportation provider

- Share freight details, including temperature sensitivity, packaging, shelf-life expectations, and any regulatory or inspection requirements

- Confirm the required operating mode (cycled or continuous)

- Your carrier or broker will plan routing to minimize transit time

- If working with a broker, a vetted carrier best suited to the shipment is selected and dispatched

Step 2: Reefer & Freight Preparation

- Trailer wash-out and drying are completed prior to arrival

- Trailer is pre-cooled or heated to the required temperature and set to the correct operating mode

- Tractor and reefer units are fully fueled before pickup

- Temperature monitoring equipment is inspected for accuracy

- Freight is pre-cooled or frozen prior to loading

- Pallets are pulped to verify internal product temperature and ensure consistency

Step 3: Loading

- Freight is packaged and palletized to support airflow and protect product integrity

- Temperatures are documented at loading

- Seals are applied and recorded on the BOL, if required

Step 4: In-Transit Monitoring

In-transit monitoring is one of the most critical safeguards in temperature-controlled transportation. Visibility into location, temperature performance, and reefer operation allows teams to identify and address potential issues early -before product integrity is compromised.

Step 5: Delivery and Verification

- Temperatures and seal integrity are verified prior to unloading

- Delivery facilities offload trailers efficiently to minimize dwell time

- Gaps between the trailer and dock are insulated when possible to reduce temperature exposure during unloading

Step 6: Post-Shipment Review

- Freight is inspected for quality, damage, or spoilage

- Any issues are documented on the BOL before the driver departs

- Issues identified after departure should be reported immediately

Choosing the Right Partner

Selecting the right logistics partner is essential. The complexity of temperature control requires experience, reliability, communication, and access to quality equipment.

A strong partner will:

- Understand commodity-specific sensitivities

- Vet carriers for equipment quality and experience

- Offer 24/7 visibility and monitoring

- Manage produce season volatility

- Provide cross-border expertise

- Support heated, frozen, chilled, and ambient shipments

- Offer cold storage options at critical border locations

The best partners act as an extension of your quality assurance program, not just your transportation team.

Best Practices

Airflow, maintenance, equipment condition, fuel management, and monitoring capabilities all play a direct role in temperature-controlled performance.

- Ensure Proper Airflow: Consistent temperature distribution throughout the trailer or container is dependent on proper airflow. Blocked chutes or improper spacing can create hot or cold pockets even when the set point is correct.

- Use Well Maintained Equipment: Improper carrier vetting can result in shipments moving on poorly maintained equipment. Worn components, faulty sensors, or deferred inspections increase the likelihood of temperature deviations.

- Set Limits on Equipment Age: While proper maintenance is the most critical factor in reefer performance, equipment age can influence how effectively a unit maintains temperature – particularly during extreme weather or extended dwell times. Newer equipment often features more efficient heating and cooling systems, improved insulation and airflow design, and more advanced temperature monitoring and control capabilities.

- Keep Fuel Topped Up: During delays, border crossings, or port congestion -when a reefer must operate independently for extended periods – a full fuel tank becomes essential to maintaining shipment integrity.

Temperature-controlled transportation is only as reliable as its execution. When any of these elements are overlooked, even properly specified equipment can fall short. Consistent loading practices, disciplined processes, and active monitoring are what ultimately preserve temperature integrity from origin to destination.

Frequently Asked Questions

No. It maintains temperature. Freight must be loaded at the correct temperature.

For sensitive freight, yes. Continuous mode avoids temperature swings that cycle mode can create.

Incorrect pre-loading temperature, blocked airflow, improper set points, and dwell times.

Temperature-controlled LTL is generally not recommended for fresh produce. Produce is highly sensitive to temperature fluctuations, airflow interruptions, and frequent door openings, all of which are common in LTL networks.

For this reason, produce typically moves in dedicated refrigerated truckload environments, where stops are minimized and temperature stability can be better controlled throughout transit.

A heated service that keeps freight above 32°F (0°C) in winter.

Fuel consumption depends on factors including equipment age, tank size, operating mode, set point, ambient temperature, and transit conditions.

Reefer units consume more fuel when:

– Operating at colder set points

– Running in continuous mode

– Exposed to extreme hot or cold outside temperatures

- Experiencing frequent door openings or extended dwell

Because consumption increases under these conditions, fuel planning must account for the most demanding scenarios, particularly during long-haul moves, border delays, or periods of congestion.

Proper fuel management helps ensure temperature stability is maintained throughout the entire shipment.